Mastering PETG 3D Print Filament: Tips for the Best Prints Every Time

Share

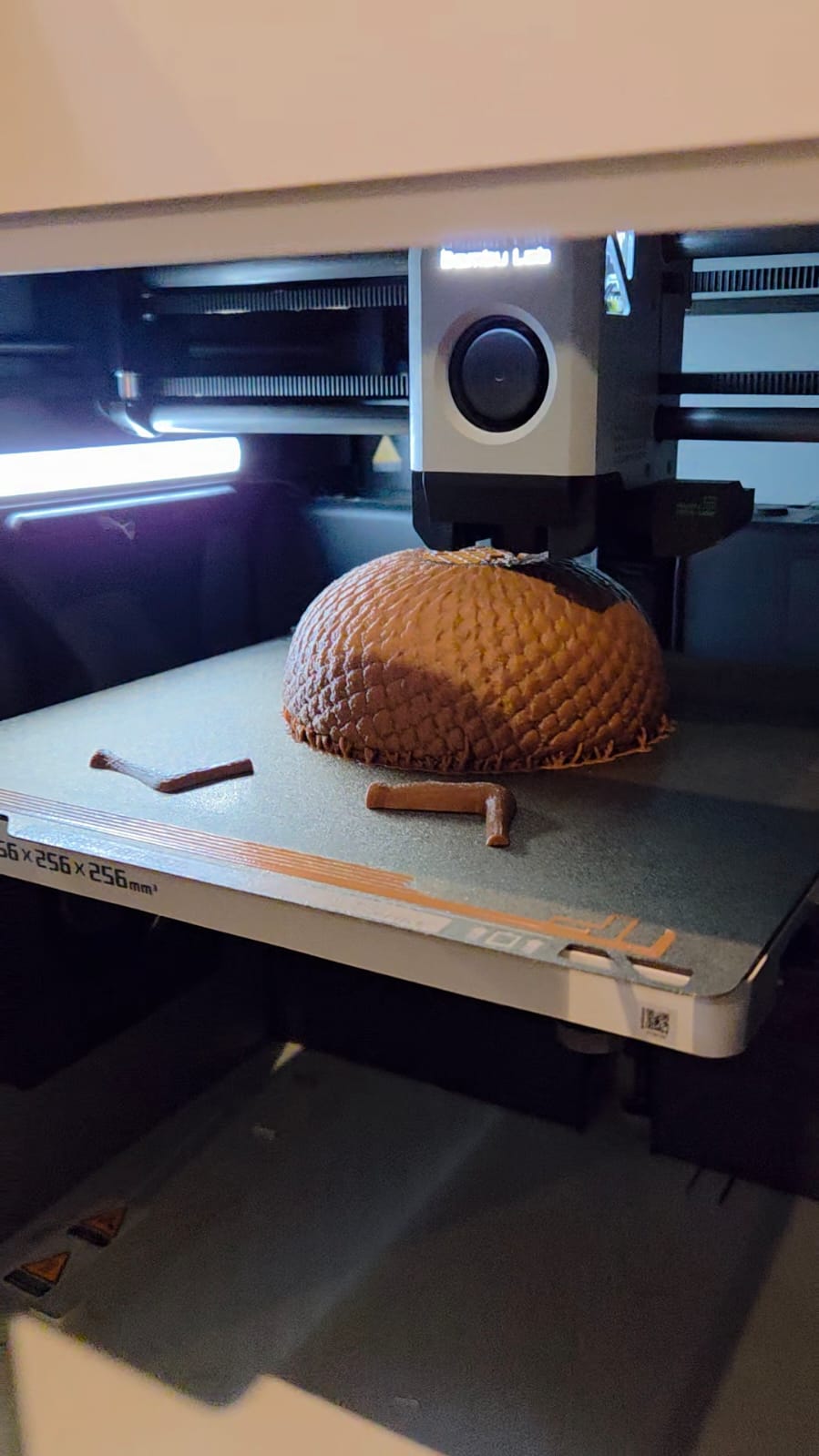

PETG filament is popular among hobbyists and small businesses for its strength, flexibility, and resistance to impact and moisture. Whether you're printing functional prototypes, end-use parts, or detailed models, mastering PETG can take your 3D prints to the next level. However, this versatile 3D printing filament requires fine-tuning to achieve the best results.

In this guide, we'll cover everything you need to know to get the most out of your PETG 3D printer filament, from optimal print settings to troubleshooting common issues.

Why Choose PETG for Your 3D Prints?

PETG (Polyethylene Terephthalate Glycol) is an excellent middle ground between PLA and ABS. It's stronger and more heat-resistant than PLA but easier to print than ABS, making it an ideal choice for hobbyists and businesses alike.

Advantages of PETG Filament:

- Durability: PETG is impact-resistant and more flexible than PLA, making it ideal for functional parts.

- Temperature Resistance: With higher heat resistance than PLA, PETG can withstand moderately high temperatures.

- Low Warping: Unlike ABS, PETG doesn't require an enclosed build chamber and has minimal warping.

- Chemical Resistance: PETG resists chemicals and moisture better than PLA, making it suitable for outdoor applications.

- Ease of Printing: While PETG requires some tuning, it is generally more forgiving than ABS.

Optimising Print Settings for PETG 3D Printer Filament

Using the right print settings is essential to achieving high-quality prints with PETG. Using the settings recommended by your filament's manufacturer is generally a great place to start, but, if you want some extra guidance, check out our tips below:

Nozzle Temperature

Depending on the brand and colour of the filament, PETG prints best at temperatures between 220°C and 250°C.

If the temperature is too low, you may experience poor layer adhesion or under-extrusion. If the temperature is too high, and you may see excessive stringing or blobs on your prints.

Starting at 240°C and adjusting based on your results is recommended.

Print Bed Temperature

To ensure proper first-layer adhesion, a heated bed set between 70°C and 85°C is ideal.

If you're having issues with the print not sticking to the bed, try increasing the bed temperature slightly or use an adhesive aid, such as a glue stick or PEI sheet. Just be careful to avoid excessive heat, as it can cause the bottom layers to soften too much which will result in the print failing.

Print Surface and Adhesion

PETG adheres well to glass, PEI, and textured build plates. However, PETG sticks very well, so it can fuse to certain surfaces and become difficult to remove.

To prevent damage you can try applying a thin layer of glue stick on the bed before printing. You could also use a removable build plate or flexible sheet to make part removal easier.

Print Speed

PETG prints best at moderate speeds. Generally, 40-60mm/s is ideal for most prints. Slower speeds help with layer adhesion and reducing stringing, while printing too fast can lead to under-extrusion or poor layer bonding.

Cooling Fan Settings

Enable 30-50% cooling for small, detailed prints to improve detail. Keep cooling off or at a low setting for large structural parts to ensure strong layer adhesion. Be careful, as too much cooling can cause weak bonds between layers.

Retraction Settings

Retraction is crucial for controlling stringing, one of PETG's most common issues.

To help avoid stringing, start with a 1-3mm retraction distance for direct drive extruders or 4-6mm for Bowden setups. Retraction speed should be 25-45mm/s to prevent clogs.

Troubleshooting Common PETG Print Issues

Even with proper settings, PETG can sometimes be tricky. Here are some common problems and how to fix them.

Stringing and Oozing

PETG is prone to stringing due to its slightly sticky nature.

Solution: Increase retraction, lower print temperature slightly, and enable combing in slicer settings.

Poor First Layer Adhesion

PETG 3D printing filament isn't sticking to the bed.

Solution: Ensure the bed is level, increase the first-layer temperature, and use an adhesive (e.g., glue stick).

Blobs and Zits on the Surface

Excess material can build up on the nozzle and be deposited onto your print.

Solution: Reduce print temperature, adjust retraction, and enable coasting in slicer settings.

Warping and Curling

While PETG has lower warping than ABS, it can still occur.

Solution: Increase bed temperature, use a brim or raft, and keep the print environment draft-free.

Post-Processing PETG Prints

PETG prints can be smoothed and refined using various post-processing techniques:

- Sanding: Start with coarse sandpaper and work up to finer grits.

- Polishing: Use a heat gun carefully to smooth the surface.

- Gluing: PETG can be bonded using super glue or specific plastic adhesives.

- Painting: PETG can be painted with acrylic paints after applying a primer.

Best Uses for PETG 3D Print Filament

PETG is used widely in many applications, including:

- Functional Parts: PETG's durability makes it ideal for brackets, enclosures, and mechanical components.

- Outdoor Prints: Its UV and moisture resistance makes PETG suitable for garden tools, signage, and more.

- Food-Safe Applications: Some PETG filaments are food-safe, making them great for storage containers and kitchen tools (ensure the filament is certified for food contact).

- Medical and Prosthetics: PETG is used for custom prosthetics and medical devices due to its strength and flexibility.

PETG filament is a fantastic choice for those looking to upgrade from PLA while avoiding the challenges of using ABS. By fine-tuning your printer settings and addressing common issues, you can consistently achieve high-quality prints with PETG 3D printing filament.

If you're after affordable, high-quality PETG 3D printer filament, check out our range at RAW3D. We stock a variety of variations, colours and brands to suit every printing need. Happy printing!